Bugatti Tourbillon Enters Early Customer Assembly Phase in Molsheim

Molsheim, France (November 2025) – Bugatti has entered a decisive new chapter in the development of its next-generation hypercar, the Tourbillon. Industry sources close to the production program confirm that the first customer-spec carbon monocoques have now moved into the early assembly stage within Bugatti’s Atelier in Molsheim.

While the company has not yet released images of the chassis stage, this milestone highlights the rapid progress Bugatti is making toward delivering the first customer cars of its radically engineered V16-hybrid flagship.

A New Era Begins in the Atelier

According to internal production planning, the initial batch of customer monocoques has passed structural verification and dimensional validation. These units have now begun the rigorous multi-stage assembly process that will shape each vehicle into its final form.

While Bugatti has not commented publicly on internal timelines, the movement of the first customer structures into assembly strongly indicates that the program remains on track for its planned delivery window, with dynamic testing, system integration and interior craftsmanship advancing in parallel.

Tourbillon: Engineering Beyond Convention

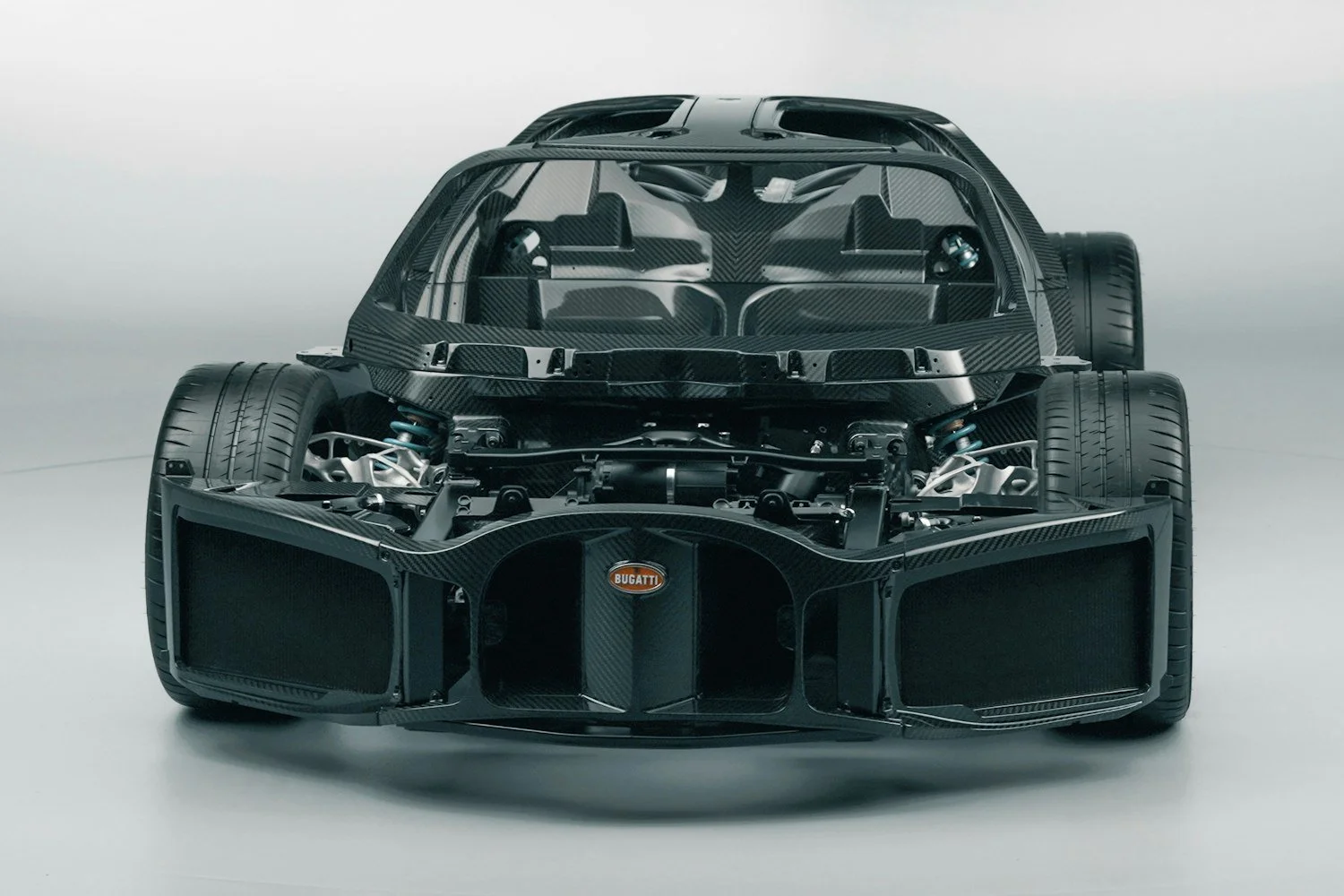

The Bugatti Tourbillon represents the most radical mechanical departure in the brand’s modern history. Its centerpiece is the bespoke, naturally aspirated V16 engine, developed in collaboration with Cosworth, paired with a three-motor electric system to create an entirely new hybrid architecture.

Key highlights of the platform include:

An ultra-lightweight carbon-aluminium hybrid monocoque

A new front and rear multi-link suspension inspired by motorsport

A next-generation aerodynamic package integrating active surfaces and high-efficiency air channels

A fully electric driving mode

A driver-focused cockpit featuring analog-inspired instrumentation blended with mechanical precision

The early assembly of customer monocoques confirms that these systems are now undergoing integration phase by phase.

Image: Bugatti Automobiles S.A.S.

The Most Ambitious Bugatti Ever Built

From its announcement, the Tourbillon has been positioned as Bugatti’s ultimate expression of mechanical beauty and performance — a successor not only to the Chiron, but to the design and engineering philosophy that began with the Veyron in 2005.

The new monocoque is central to the Tourbillon’s identity. Designed for maximum rigidity and safety, it forms the structural backbone for:

The 16-cylinder power unit

The fast-charging hybrid modules

The battery pack architecture

The next-generation electrical system

The multi-layer aerodynamic tunnels

Every component is mounted with near-watchmaking precision, following Molsheim’s traditional hand-assembly principles.

No Official Production Images – Yet

As expected for this early stage, Bugatti has not released photographs of the customer chassis or internal assembly procedures.

This is standard practice: early-stage manufacturing at Bugatti is typically kept confidential until the brand is ready to reveal specific milestones publicly.

For now, Bugatti continues to share only official studio photography of the finished Tourbillon, along with images of the Molsheim Atelier that convey the brand’s craftsmanship and production philosophy.

A Major Step Toward Customer Deliveries

The transition of the Tourbillon into its first assembly stages marks one of the most critical milestones of any Bugatti project. With customer monocoques now taking shape on the Atelier floor, the next key phases include:

Full drivetrain integration

Calibration of hybrid systems

Validation drives on road and track

Interior tailoring and personalization

Final quality certification ahead of delivery

Given Bugatti’s meticulously curated production process — historically limited to approximately 80 cars per year across all models — the assembly of even the first few Tourbillon units is a significant moment.

Conclusion

The Bugatti Tourbillon’s path toward production continues with precision, craftsmanship, and an almost obsessive attention to detail.

With the first customer monocoques now in early assembly, the next-generation Bugatti hypercar is officially transitioning from an engineering vision into physical reality.

As the Tourbillon moves closer to first deliveries, it is poised to redefine what a modern hypercar can be — not only through performance, but through the mechanical artistry and bespoke craftsmanship that define the Bugatti name.

Affiliate Disclosure

Bugatti Bolide W16.4 year 2020 blue / carbon 1:18 Bburago

Disclosure: Some of the links on this website are affiliate links. This means that if you click on one of these links and make a purchase, we may earn a small commission at no extra cost to you.

We only recommend products and services that we trust or that are directly relevant to our content. Affiliate earnings help us keep this platform independent and of high quality.