Rimac Technology Unveils New Solid-State Battery Tech and Next-Generation e-Axles at IAA Mobility 2025

Munich, Germany – Rimac Technology has once again redefined the future of electrification by unveiling a portfolio of next-generation solid-state batteries, advanced hybrid solutions, and high-performance e-Axles at IAA Mobility 2025. The innovations reinforce Rimac’s role as a leading Tier 1 supplier, supporting global OEMs with scalable, production-ready solutions designed for the coming decade of mobility.

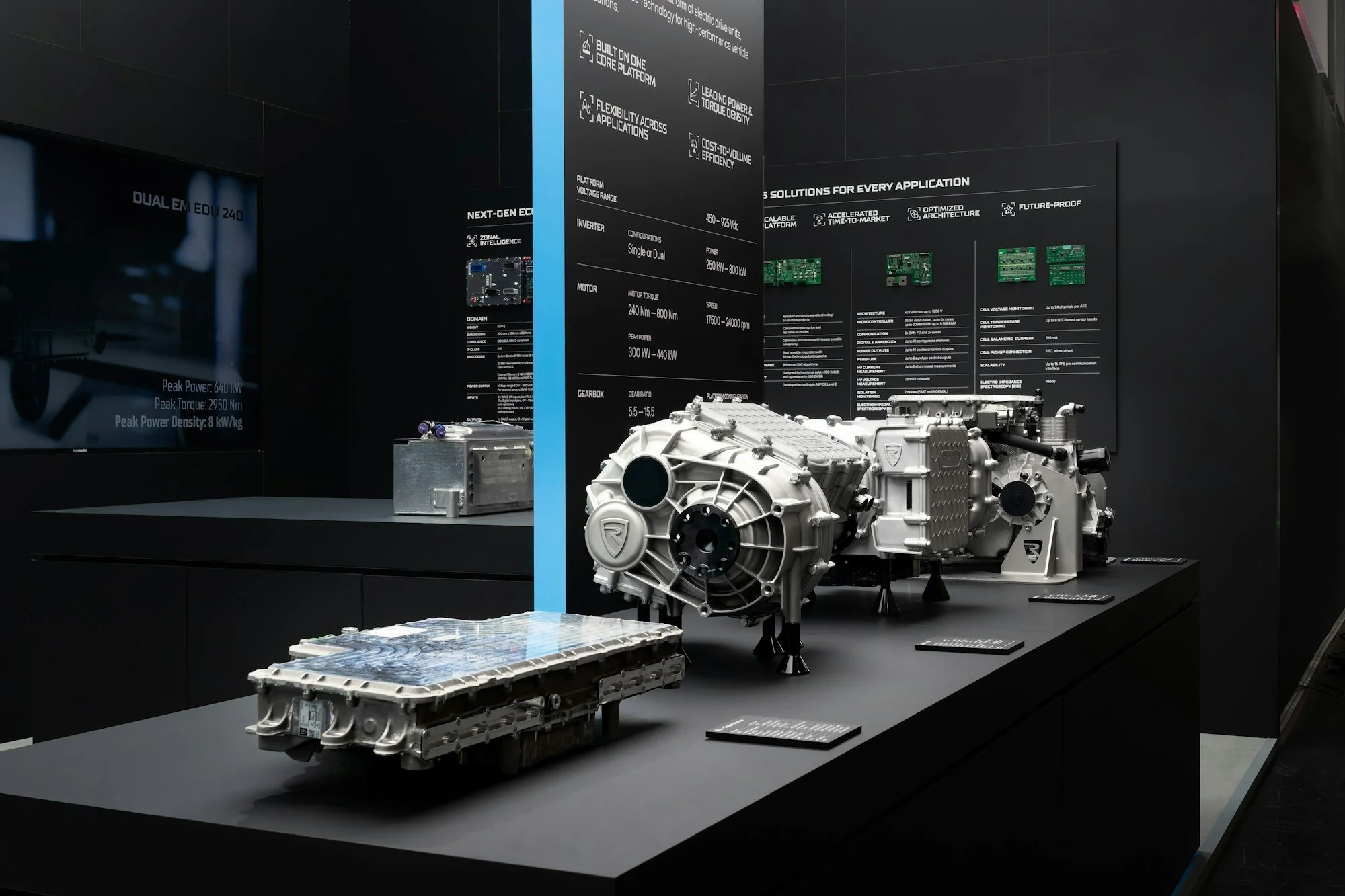

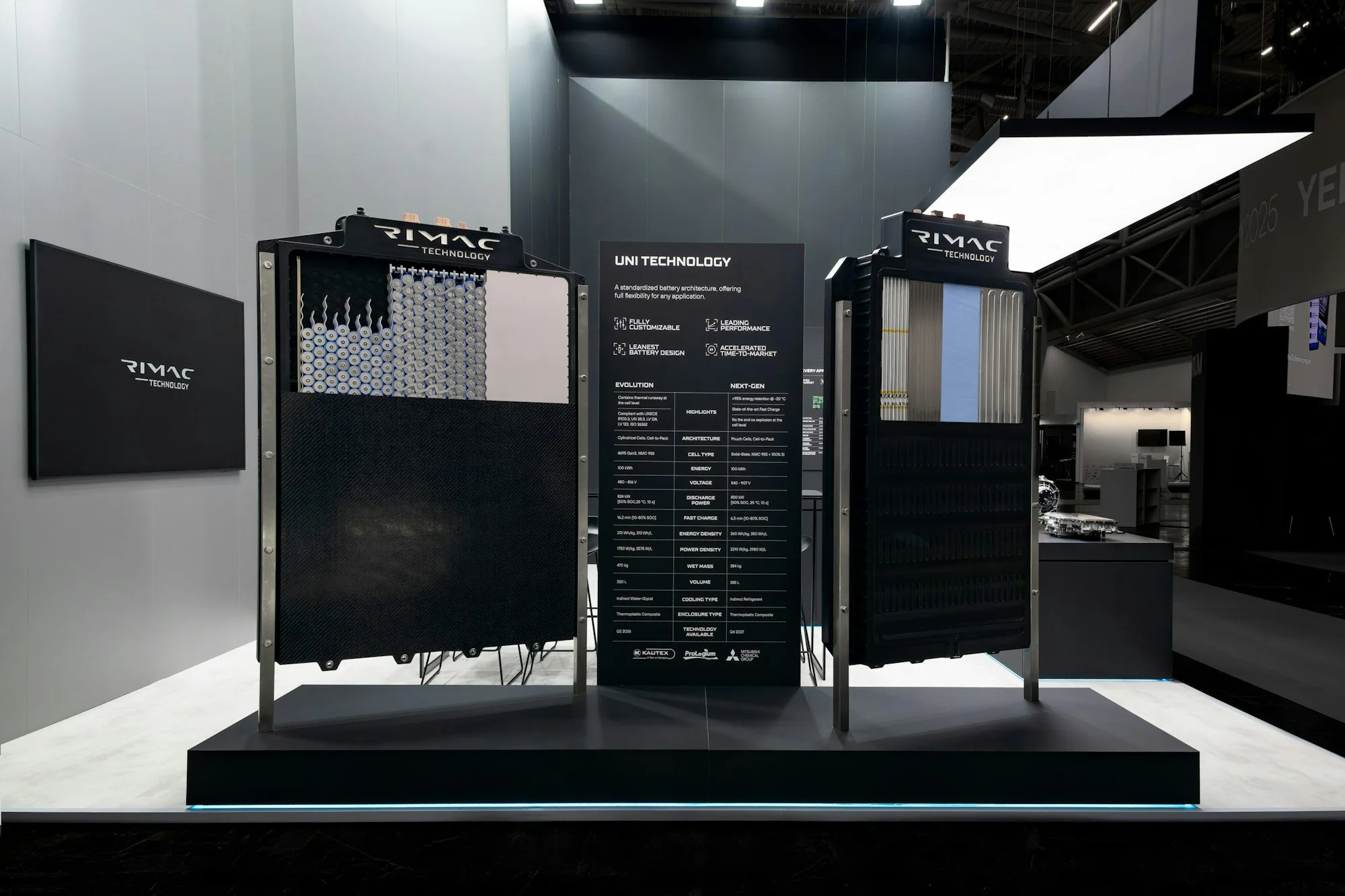

Breakthrough Battery Platforms

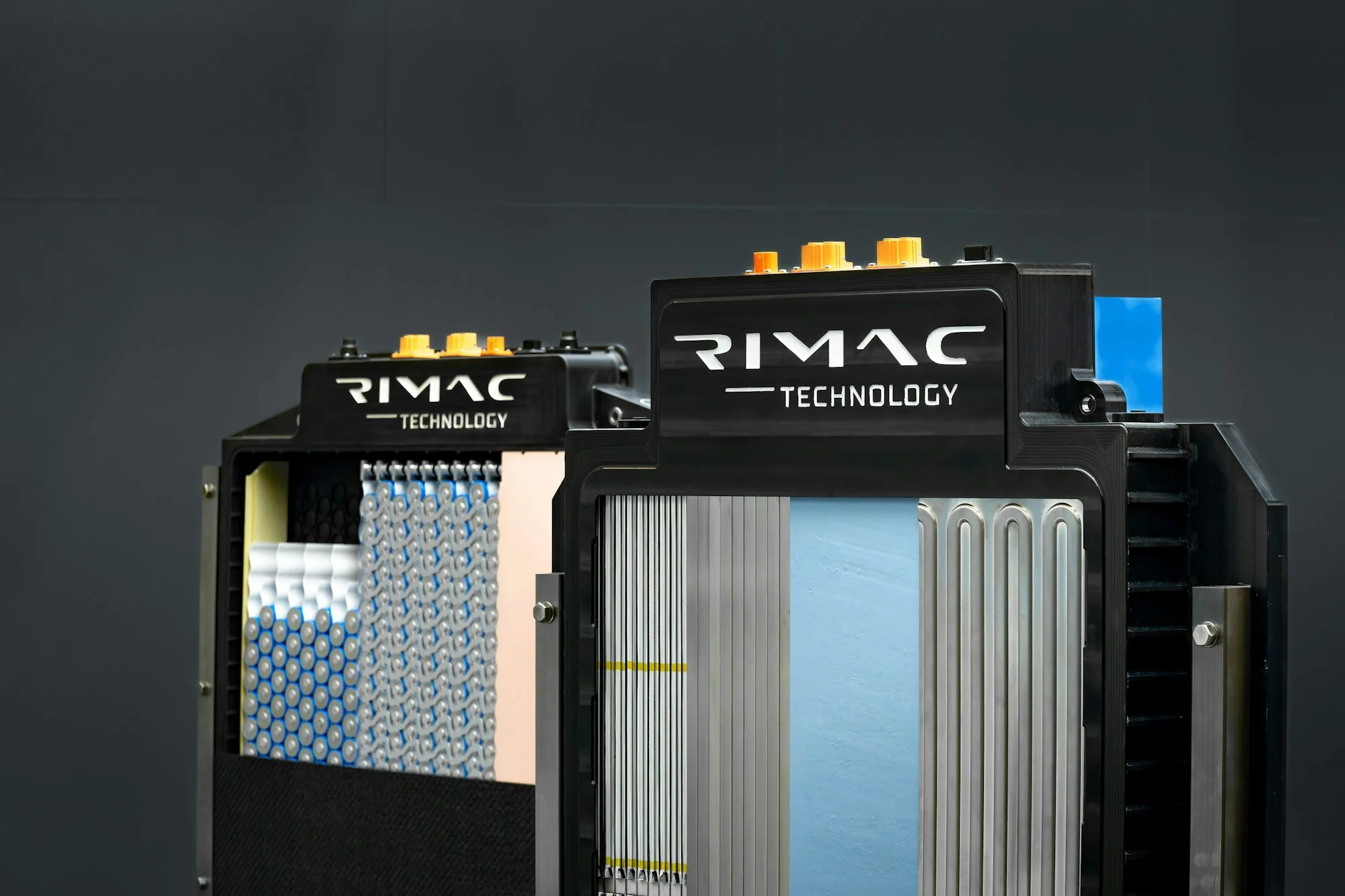

Rimac introduced three new platforms that cover the spectrum of high-performance and high-volume applications:

Next-Gen Solid-State Battery – Developed in partnership with ProLogium and Mitsubishi Chemical Group, this battery leverages cutting-edge solid-state cells with advanced materials to deliver higher energy density, greater safety, and reduced weight.

Evo Technology – Built around 46XX Gen2 NMC cells and co-developed with Kautex Textron, this solution incorporates thermoplastic composite housings for optimized packaging, cooling, and scalability.

Hybrid Technology – Offers scalable packs based on both 46XX and 2170 cell formats, balancing high energy density with power-focused performance in a cell-to-pack architecture.

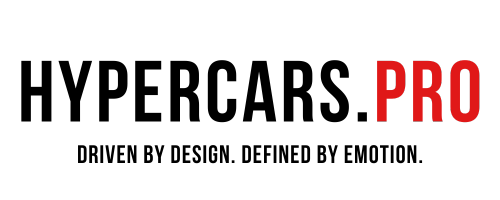

Next-Generation Powertrains

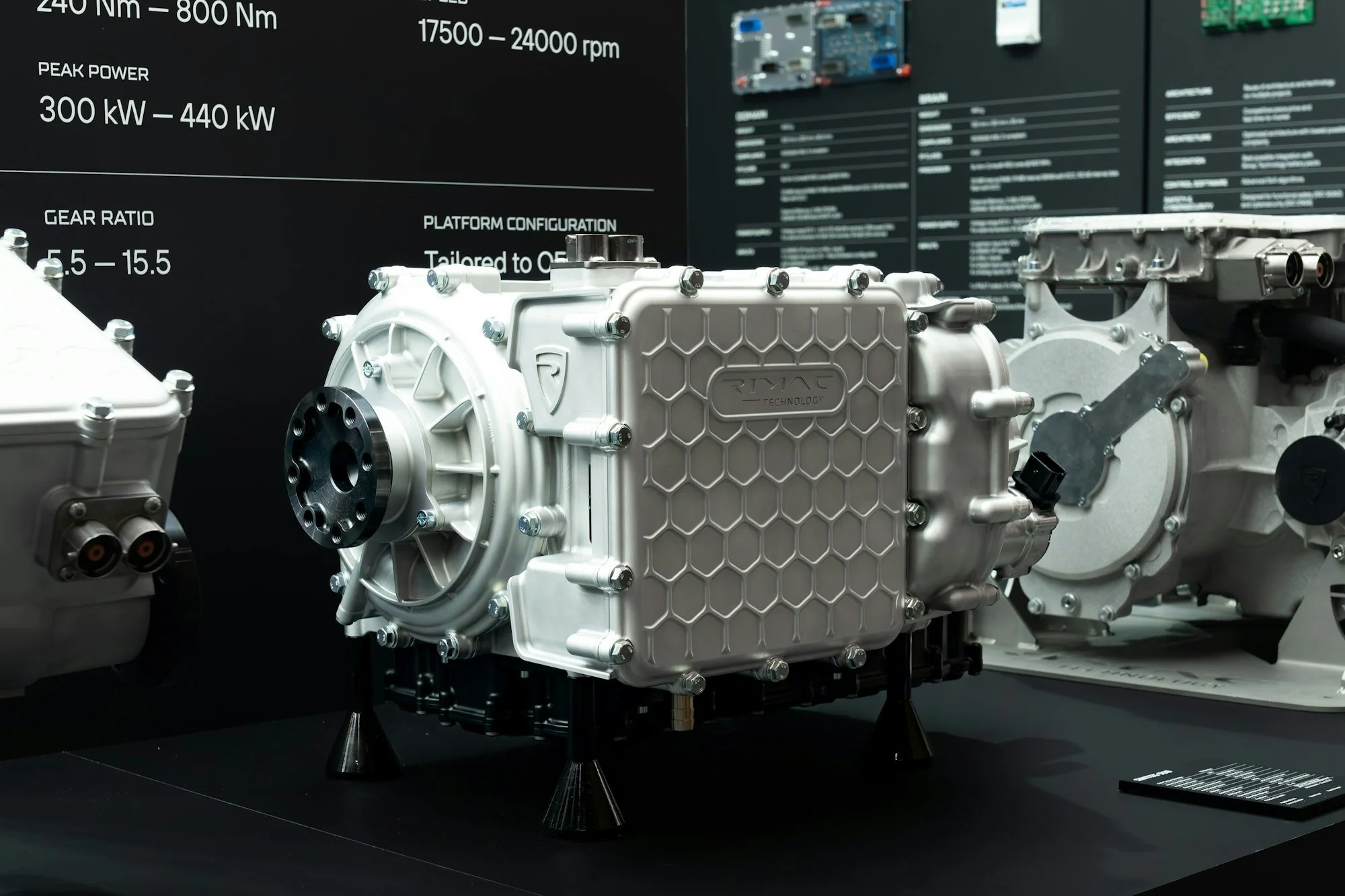

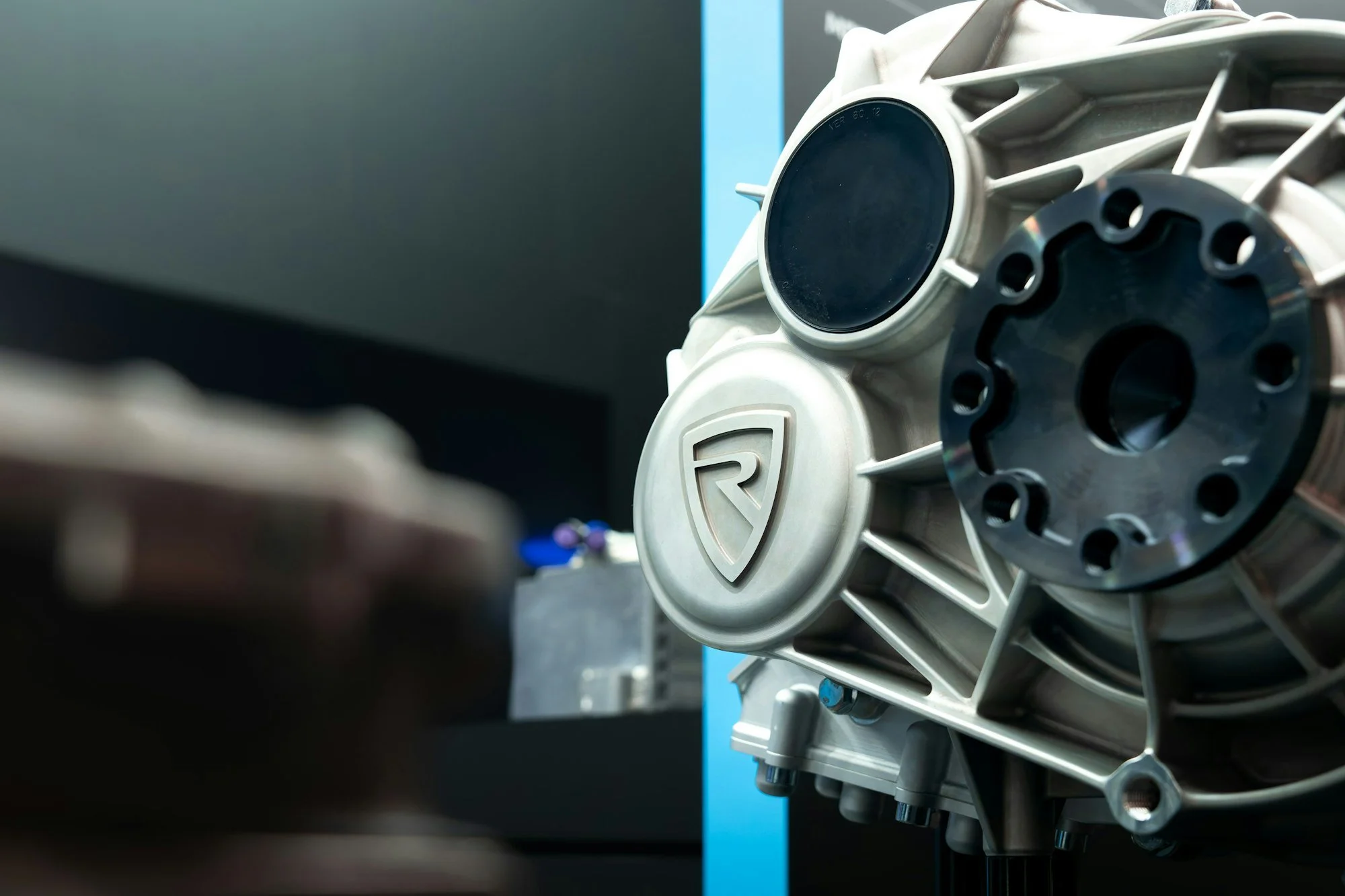

Rimac also presented its most advanced electric drive units (EDUs) to date:

SINTEG 300 & 550 eAxles – Ultra-compact single-motor systems with power density over 8 kW/kg and torque density above 90 Nm/kg. Capable of spinning up to 25,000 rpm, these eAxles deliver 150–360 kW and 2,500–6,250 Nm, ideal for applications from hot hatches to high-performance SUVs.

High Torque XXL Axle – A production-ready Dual EM EDU 550 system, delivering over 11,000 Nm of axle torque at >95% efficiency. Scheduled for series production in 2026, it will power vehicles from a global OEM partner.

Electronics and Controls

Rimac is also streamlining vehicle architecture with domain and zonal ECUs powered by NXP’s S32E2 processors. These controllers consolidate multiple traditional ECUs into a centralized system that reduces cost, complexity, and weight while enabling software-defined vehicle functions such as:

Torque vectoring

Battery and thermal management

Body and power distribution controls

Over-the-air (OTA) updates

This approach ensures real-time safety, scalability, and performance for OEM partners.

Image source: Rimac Automobili

Industrial Scale with Production Readiness

The technologies showcased at IAA are not just concepts. Rimac confirmed they are production-ready, designed to be scaled to hundreds of thousands of vehicles globally. Manufacturing will take place at Rimac’s state-of-the-art facilities in Croatia, including the €200 million Rimac Campus, which spans over 95,000 m² of production capacity.

Nurdin Pitarević, COO of Rimac Technology, emphasized:

“What we’re showcasing at IAA represents the convergence of breakthrough innovation and production readiness. These aren’t simply concepts – they are real solutions ready for the road.”

Conclusion

With its latest solid-state battery innovations, high-performance eAxles, and advanced electronics platforms, Rimac Technology continues to lead the charge in electrification. By combining innovation with industrial readiness, the Croatian company positions itself as a crucial partner for automakers worldwide – powering the next era of performance, sustainability, and scale.